Screw Jacks, Linear Actuators, Lead Screws, Bevel Gearboxes and Jacking Systems.

A screw jack is a gearbox assembly (either worm gear or bevel gear) and a transmission product (lead screw, ball screw or roller screw) which through use of a motor is used to convert rotary into linear motion. They can be used to push, pull, tension, lock, unlock, tilt, pivot, roll, slide and lift or lower loads, anything from a few kilos to thousands of tonnes.

How a Screw Jack Works Screw Jack Products

A linear actuator is a device that moves between two points in a linear motion. Linear actuators are available based on a variety of technologies including: Mechanical, Electro-Mechanical, Direct Electric (Linear Motors), Hydraulic & Pneumatic. All of Power Jacks linear actuators are either mechanical or electro-mechanical.

How a Linear Actuator Works Electric Linear Actuators

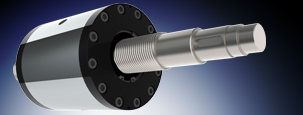

A lead screw turns rotary motion into linear motion combining a screw and a nut where the screw thread is in direct contact with the nut thread. With roller screws, the rollers rather than the nut are in direct contact with the screw thread offering greater efficiency. Power Jacks can manufacture a lead screw as either rolled, ground or machined using a whirling process.

How a Lead Screw Works Lead Screws

A bevel gearbox is a device used to transmit and/or split/distribute the power of a singular rotating mechanical drive shaft through a defined angle, typically 90°. Though most bevel gearboxes operate at 90° angles other angles are also available, both acute (less than 90°) and obtuse (greater than 90°).

How a Bevel Gearbox Works Bevel Gearboxes

These jacking system arrangements or configurations can be built in many formats with the use of bevel gearboxes, motors, reduction gearboxes, drive shafts, couplings, plummer blocks and motion control devices.Four of the most popular system configurations are the ‘H’, ‘U’, “T” and “I” configured jacking systems.

How a Jacking System Works Jacking Systems