Using electro-mechanical screw jacks to tension floating wind mooring systems

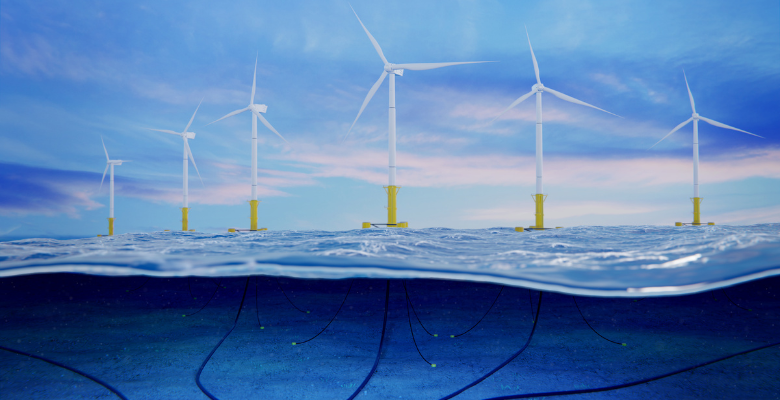

We have been exploring applications for our 200Te electro-mechanical screw jacks as a tensioning component within the mooring systems for floating wind turbines. These large screw jacks can be used to keep the structure in position in even the harshest wind and wave conditions.

With the infancy of the floating offshore wind sector, we are keen to work with industry partners and explore potential applications of our electro-mechanical lifting and positioning products within floating wind applications. Electro-mechanical systems have a number of benefits over hydraulic alternatives including no risk of fluid leaks, greater efficiency as no power is required to hold the load and higher precision.

The UK Government has announced its ambition to deliver up to 50GW of offshore wind by 2030 including up to 5GW of floating wind. With a current installed capacity of around 12GW the rate of installation needs to increase dramatically and floating wind farms play a key role in this. Floating wind technology enables wind farms to be developed in much deeper waters where winds are stronger and more consistent meaning increased capacity over fixed wind farms. There are also installation benefits as the floating foundations can be installed onshore and then towed offshore resulting in lower costs, lower safety risks and a boost to local supply chains.

The UK Government have also made clear their commitment to 60% local content with the manufacturing of floating substructures and floating anchoring and mooring systems identified as a key strategic priority for components manufacturing in the UK. As a Scottish-based business we have long supported the UK manufacturing and energy sectors and look forward to playing a part in the energy transition.

To discuss your floating offshore wind application please feel free to get in touch with us on sales@powerjacks.com.