Enhanced safety in steel manufacturing with electro-mechanical jacking systems

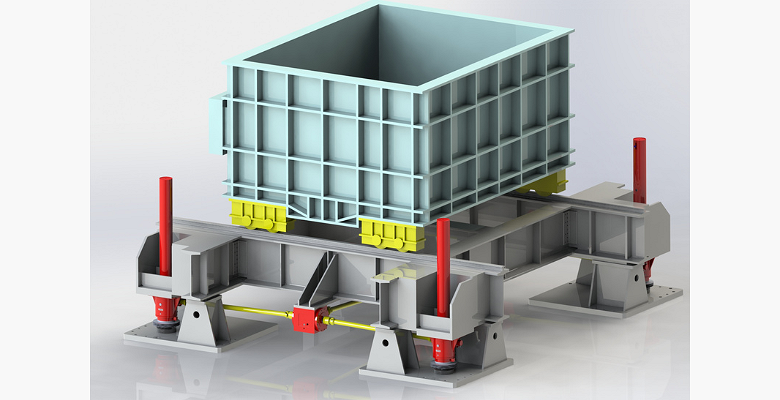

Power Jacks’ jacking systems are enhancing safety in steel mills across the globe. For over 20 years Power Jacks has been supplying its electro-mechanical jacking systems to lift and lower the zinc baths used as part of the galvanising process. The system is used when the zinc baths need to be changed out and depending on the load, will use four 150Tn or four 200Tn screw jacks arranged in a H-configuration which are mechanically synchronised offering high positional accuracy.

The system was first developed for a customer who was using a combination of screw jacks and hydraulics but looking to move to a purely electro-mechanical system. With a purely electro-mechanical system, once the motor stops the load is still held in place, so this brings a host of benefits over hydraulics which require continuous power to hold the load. As well as creating great inefficiencies, this also poses a high safety risk in the event of power loss or system failure which is common with the various pipes, seals and hoses that operate hydraulics.

The zinc bath temperatures are usually in the temperature range of 455 to 470°C and weigh in the region of 360 – 500 tons so there are huge risks when moving this load and an electro-mechanical system can offer greater assurances concerning health and safety.

Power Jacks also customised the jacking system to include a range of monitors that ensure the system is operating safely and efficiently. There is a rotational motor located on the on the gear which detects at an early stage when a gear is out of sync meaning this can be remedied before causing a greater issue. There is also a wear monitor which monitors the level of wear on the gear & lead screw and can again flag this before it becomes a risk. Lastly there is a temperature monitor that ensures the screw jacks don’t overheat when in use.

With this application, the zinc baths tend to be changed out every few weeks so the jacking system tends to be low duty however the Power Jacks team have been exploring higher duty applications and in this instance an oil cooling system can be included which allows the screw jacks to run more frequently without overheating.

Over the past 20 years Power Jacks has supplied over 15 of these systems which are seeing success in steel mills across the globe including in Brazil, China, Russia and India.