Antenna dish for major communication systems, transmitting television programmes, telecommunications and business data.

Power Jacks screw jacks for accurate positioning of elevation and azimuth of large antenna dishes. Low axial backlash and high stiffness are required to maintain antenna dish on station under high fluctuating wind loads.

Screw Jack Provides Elevation Drive for AMI Antenna Dish Positioning used for detecting galaxy clusters at University of Cambridge.

The Cavendish Laboratory based in West Cambridge is part of the University of Cambridge’s School of Physical Sciences and has a world renowned history of discovery and innovation in physics. Power Jacks designed and manufactured a precision elevation drive for The Arcminute Microkelvin Imager (AMI) antenna dishes. The elevation drive is based on a 50kN ball screw jack and positions the AMI so it can carry out surveys on galaxy clusters. For more details please read our case study.

This Case Study and More is Available in the Portal section of this website. Login or Register Here

Already Logged In to Portal Then Download Case Study Here

The Channel tunnel, also known as Chunnel tunnel or Eurotunnel, is a railroad tunnel beneath the English Channel connecting Coquelles, Pas de Calais region in France and Cheriton, Kent in England. The tunnel has a length of approximately 50 km, of which 37 km are under the English Channel.

The tunnels were mainly constructed about 40 m under the sea bed. The Channel Tunnel comprises 3 separate tunnels. The outer North and South Running Tunnels of 7.6 m diameter are 30 m apart, with each containing a single lane railroad line. The middle Service Tunnel of 4.8 m diameter is for maintenance and emergency. The Running Tunnels are connected to the Service Tunnel by cross passages at every 375 m. The two Running Tunnels are also connected by Piston Relief Ducts of 2 m diameter at every 250 m to balance the air pressure due to the “piston effect” caused by the passage of trains.

The cross-passages have a fire-resistant door at the exit of each cross-passage into the Running Tunnel. This door is normally closed. The service tunnel to which they connect is maintained at a higher level of air pressure than that of the Running Tunnels to prevent smoke from entering the Service Tunnel and allow a “bubble effect” to be created at the opening of a cross-passage door. At the main entrance to each service tunnel there is an airlock (1 at each end). Both the cross-passage doors and the service tunnel entrance doors need a mechanical mechanism to open and close the doors due their weight and size. At the heart of this mechanism is an E-Series metric ball screw jack chosen for its high efficiency and robust design. The screw jacks used are 100kN inverted translating metric ball screw jacks with clevis ends and additional features of: Anti-rotation mechanism for the ball screw. This is achieved by using a square cover pipe to guide a square profiled nut on the end of the ball screw. Electric motor mounted directly to the screw jack for automated opening and closing of the door. Bevel gearbox mounted on the opposite side to the motor provides a driveshaft at 90° for a hand wind facility so the door can be operated even if the electricity fails. The complete unit illustrates the flexibility in design solutions for the E-Series screw jack range and its uses in a safety environment.

Power Jacks 250°C rated Rolaram linear actuator with ball screw drive is fitted onto each damper.

Power Jacks Rolaram linear actuator with ball screw drive is fitted onto each damper. This Rolaram actuator is a special design with a pre-loaded spring and is fitted with a high temperature brake motor. The internal spring and drive configuration will allow the ram to retract automatically in the event of power failure. Three adjustable limit switch positions are provided and the stroke can be set within allowable 120mm, by adjusting these switches. All components are selected for the appropriate approved temperature requirement. The actuator has a fire test certificate for operation at 250°C for 1 hour.

When a patio door is not enough just automate the entire wall of the building using screw jacks!

For a bespoke house design in the UK a patio door was not enough to bring outside living inside. Instead automation to raise and lower 2 walls of the house was installed using Power Jacks screw jack systems. 100kN E-Series machine screw jack systems were used to automate the corner and side walls of the house.

Read the more about this story in the case study.

This Case Study and More is Available in the Portal section of this website. Login or Register Here

Already Logged In to Portal Then Download Case Study Here

This example is a house, but building automation can be applied to factory doors, flexible stadium seating or in the case of Wimbledon an automated roof. All benefit from Power Jacks electro-mechanical screw jack and linear actuator motion solutions.

These linear actuators used for locking and unlocking the roof segments were specially designed by Power Jacks for the Wimbledon roof using 3D design technology.

These linear actuators used for locking and unlocking the roof segments were specially designed by Power Jacks for the Wimbledon roof using 3D design technology. The actuators design: based on Power Jacks Type-A Rolaram® technology. Has been used worldwide in varying industry sectors including automotive, medical, steel and nuclear. Each of the Wimbledon Rolaram’s® is designed to have a peak load rating of 160kN to withstand forces exerted by nature.

They operate at 1500 mm/min over a 400mm stroke with the useable stroke set by limit switches integrated into the actuator. Drive for the actuator is provided by an electric brake motor with an IP66 weatherproof enclosure. Both the motor and the limit switches connect to the electrical control and power systems via plug-in connectors for quick and easy installation. The completed Rolaram® actuator is mounted in the roof using a trunnion to clevis type arrangement that allows the actuator to pivot through an arc as it operates.

Read the more about this story in the case study.

This Case Study and More is Available in the Portal section of this website. Login or Register Here

Already Logged In to Portal Then Download Case Study Here

The Rolaram Electric Linear Actuators are going to be used again for Wimbledon No.1 Court Roof due to go into service for Wimbledon 2019.

Read the full article here

Power Jacks products have been utilised to provide a world class training facility for athletes at the Western Australian Institute of Sport (WAIS) High Performance Service Centre.

The height adjustable runway allows those training in specialist pole vault and long jump activities with opportunities to maximise training without the inconvenience of a fixed ramp. Elevating the ramp allows the long jumper or pole vaulter to generate a higher speeds over a shorter distance; this saves energy which can then be applied in performing the vault or jump. The runway operates from the flat to being raised 1.5m high at one end. In the flat or elevated state it is critical the surface stays firm and stable for athletes safety and performance. Our screw jacks provided the best solution delivering precision, reliability and low maintenance.

Two of Power Jacks B100 Rolaram actuators, both parallel drive configurations with ball screw drive.

Two of Power Jacks B100 Rolaram actuators, both parallel drive configurations with ball screw drive, are fitted on each x-ray table and they are synchronized for horizontal and vertical positioning through a complex servo control system. The actuators are tested to withstand 8 times the maximum load, without catastrophic failure and producing only minimal noise. Due to space constraints, they are of a compact design and conform to strict aesthetic criteria.

Power Jacks products are being used to protect people and property in a community which has experienced major flood problems in the past.

The lifting and positioning specialist provided a set of electric linear actuators which play a pivotal role in averting the build-up of debris in a waterway during flood events.

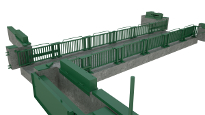

The actuators are used to lower bridge railings which would otherwise gather objects caught up in the flow – materials such as tree branches have previously combined to form a barrier that exacerbates local flooding.

Power Jacks worked with main project contractor ECS Engineering Services, delivering a total of four Rolaram actuators in support of the latest flood defence improvement works in the Yorkshire village of Skinningrove.

“It’s good to see one of our key product ranges being used to help safeguard a community that’s suffered extensively from flooding,” says Power Jacks Marketing Director Bruce Hamper. “We were pleased to contribute to a project that has not only significantly enhanced the local flood defence infrastructure, but was completed on time and to budget.

“It once again demonstrates how our products can be applied to great effect in a highly diverse range of engineering and industrial settings.”

The most recent work at Skinningrove – instigated by the local council, the Environment Agency and local residents – has been designed to further improve local defences which have taken shape since two major flood events in 2000.

The introduction of the automated system to lower the railings on Stone Row Bridge from a vertical to horizontal position – a task which was previously done manually – enables local flood wardens to focus their efforts on closing flood doors which form part of the wider defence network in the area.

A review of the arrangements indicated that there was not always enough time to safely lower the barriers by hand before the flood doors had to be closed.

Chris Leary, Operations Manager for ECS, says: “This scheme aims to improve the speed of response as well as the integrity of the existing defences and thereby provide better protection for the local community.”

Find out more about the Rolaram Linear Actuators in our Case Study.

This Case Study and More is Available in the Portal section of this website. Login or Register Here

Already Logged In to Portal Then Download Case Study Here

S-Series screw jack opens and closes a weir gate to control the flow of a river in support of a major hydro-electric plant.

100kN S-Series rotating screw jack in a ram style linear actuator design together with motor and reduction gearbox, for a weir system on the River Morar, near Mallaig on Scotland’s west coast. The weir near a hydro-electric dam and a fish ladder at the western end of Loch Morar is an important part of the region’s river system.

More details about the application and the screw jack design can be found in the application study, which you can download for free.

This Case Study and More is Available in the Portal section of this website. Login or Register Here

Already Logged In to Portal Then Download Case Study Here

The velocity of the water over the ladder has to be great enough to attract the salmon to the ladder, but not so great that it washes the salmon back downstream or causes exhaustion to the point that they cannot continue their journey upstream.

The jacking system has operated successfully for a number of years and uses 2 screw jacks to lift the ladder. 50kN E-Series rotating screw jacks were selected with stainless steel lead screws. A drive shaft mechanically links the jacks worm shaft so they can be driven synchronously by one electric motor. The ends of travel for the screw jack are signalled by an electro-mechanical limit switch in each direction.

One Rolaram electric linear actuator is fitted on each weir gate and has several special features.

This application is in a remote location and an electro mechanical solution was preferred over hydraulics due to low power requirements, no expensive hydraulic power pack, no hydraulic fluid leakage i.e. no water contamination and minimal maintenance. The Rolaram actuator used is the R175 for moving a dynamic load of 150kN at 240mm/min over a 2700mm stroke while being able to sustain a static load of 330kN.

For the complete range of brochures, datasheets, videos and more go to the Downloads page