Gearbox to drive the flail assembly of land mine clearance vehicle.

Range N, Series 40, Ratio 2:1 bevel gearboxes selected. The unit was selected for its compactness for mounting in the flail drive, however the unit needed greater power than the current designed unit. Up rated gears designed and fitted to the unit. Unit design also capable of great shock loads.

Two of the bevel gearboxes are power driven and the third is used as a hand wind facility, all units are used in the elevation of the gun, prior to its use.

The Howitzer had been in development for over 3 years and a further 5 years working closely with BAE Systems (VSEL) to ensure that the units meet the design requirements. Developed with BAE with extensive testing and trials.

Three units are supplied per Howitzer, each one different, two are based upon the standard N35 gearbox design and the third is a bespoke design based around a set of N35 gears. Many different prototypes were manufactured and tested in vigorous terrain and weather conditions, each design slightly different until the final design was settled upon.

Bevel gearboxes provide drive for the automated munitions handling system. 8 gearboxes are used per self propelled gun (SPG).

High precision and repeatability required, along with high performance and low maintenance.

Range N, Series 35, Ratio 1:1 bevel gearboxes selected. Units built with minimal backlash to aid with the repeatability and high precision of movement required and filled with high quality lubricant, allowing units to be sealed for life. The compact design of the units kept the whole design into a minimal footprint allowing more room for operators of the turret.

Actuation of the rear door of the British Army Personnel Vehicle.

The door weighs 240kg, but at compound angles of 30° can weigh up to 2.6 tonnes.

Power Jacks 24VDC Electro-mechanical linear actuator, fitted with a Ø25 x 25 ball screw and nut and 25:1 non reversible gear. The unit is also fitted with a safety clutch and limit switches and suppressed to avoid radio interference. The actuator can be submersed in water and has to be able to operate immediately whilst the vehicle is out of the water.

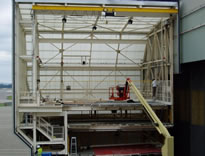

Installation of a jacking system at RAF Brize Norton which lifts one of the levels of a aircraft maintenance platform up and down.

The jacking system consists of 5 x Special DE1811 E-Series machine screw jacks arranged in a “U” configuration with 2 x Neeter Drive Range-N 35-Series bevel gearboxes and 1 x 37-Series bevel gearbox. All driven by a 5.5kW electric motor.

Linear motion and mechanical power transmission systems for the advanced weapon handling system for the Royal Navy’s CVF Queen Elizabeth class vessels.

The HMWHS (Highly Mechanised Weapons Handling System) uses electro-mechanical handling technology to move pallets of munitions in the magazine and weapon preparation areas of the aircraft carrier.