More Accurate Positioning for Better Tension Control in Subsea Cable Laying Tensioner by using electro-mechanical Screw Jacks for the positioning of the lower tracks.

For submarine cable laying maintaining tension in the cable within required tolerances is critical during the laying process to minimise the risk of cable damage due to cable cores being crushed or the minimum bend radius being exceeded. To regulate this tension specialist machines are used to handle the cable as it is laid. One such machine is the 45Te 4-Track Tensioner made by MAATS Tech Ltd, which features electro-mechanical screw jacks for the positioning of the lower tracks. The use of screw jacks on the lower tracks gives this MAATS tensioner the advantage of more accurate positioning for better tension control compared to hydraulic only systems.

This Case Study and More is Available in the Portal section of this website. Login or Register Here

Already Logged In to Portal Then Download Case Study Here

The largest pressure vessel rated at 5000psi SWP, weighs in at 138 tons with a 35-ton lid.

The screw jacks were special units based on Power Jacks E-Series 300kN Metric machine screw jack. They were of the inverted type incorporating wear monitoring for the gear sets. A motorised reduction gearbox with bevel gearboxes to direct the drive line provided drive to each of the four screw jacks. The motor unit included an integral brake for secure load holding while parked. For positioning purposes a rotary cam limit switch was connected to the jacking system, providing emergency over-travel limits and normal system stop limits.

This Case Study and More is Available in the Portal section of this website. Login or Register Here

Already Logged In to Portal Then Download Case Study Here

At a depth 3000 metres below sea level, Power Jacks Neeter Drive.

Bevel gearboxes are in operation on subsea single bolt clamp connectors on subsea retrievable chokes.

For this application a special high torque, subsea variant of the Neeter Drive Range-N Series-39 gearbox was designed. The gearbox features precision spiral bevel gears, reinforced drive shafts and of course special subsea sealing with pressure compensation connections.

Screw Jack System Provide Safe Work Access for Nuclear Containers at Dounreay. The jacking system raises and lowers the access platform that goes around the container for lid release or fixing.

At Dounreay Nuclear facility drums containing waste pass through the import / export section of the cementation facility where they need to be removed from their transportation container. A screw jack system using 50kN E-Series machine screw jacks and Range-N bevel gearboxes in an H-Configuration is used to raise and lower the platform.

This Case Study and More is Available in the Portal section of this website. Login or Register Here

Already Logged In to Portal Then Download Case Study Here

Developed by BNS Nuclear Services with whom Power Jacks worked in close partnership.

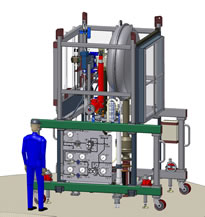

Design and manufacture the main linear actuation unit engaging the machine with the reactor standpipe. Four additional screw jacks act as stabilisers when the machine is coupled to the standpipe.

The linear actuator is designed to lift and lower the 20kN load over a stroke of 525mm with the end of travel signalled by proximity sensors installed in the actuator. To maintain a rigid column over the stroke the actuator has two internal guidance mechanisms for the ram. As a safety feature the ram is fitted with a proprietary clutch to act, as a mechanical fail safe, to prevent an overload condition should external control systems fail. Powering the actuator is a 0.75kW motor with integral brake.

This Case Study and More is Available in the Portal section of this website. Login or Register Here

Already Logged In to Portal Then Download Case Study Here

Dynamically balanced manipulators for handling radioactive materials.

EMA linear actuators are used to move the slave arm relative to the master arm in a tilt and skew motion. The actuators are an integral part of the mechanism and act as load bearing struts, carrying the full reactive loads. The models used are the 5kN and 2.5kN continuous (model C) with 24VDC motor.

Container handling system for British Nuclear Fuels Ltd.

4 off A075 Rolaram linear actuators operate a scissor lift mechanism, which raises and lowers containers as part of the encapsulation process.

For photovoltaic (PV) or concentrated solar power (CSP) technology based solar power plants it is advantageous for the PV cell or CSP mirror to track the sun to provide the highest electricity yield.

Power Jacks solar positioning solutions are customer specific and our range of screw jacks and linear actuators can accommodate even the biggest of tracking systems.

Power Jack products have a proven record in arduous environments, delivering quality trouble-free operation for decades. Products Used:

Our screw jacks can be used in the factory automation for the manufacture of wind turbines, in the construction of wind turbines at site and even on the wind turbines themselves.

Wind turbine blade manufacture can be automated by the use of screw jacks to open and close the mould used for blade production. Hinges on the mould can be driven by screw jacks to give a full 180 movement for the mould. This type of tilt & pivot movement typically needs the screw jack to pivot as it extends and retracts resulting in the use of motorised screw jacks with double clevis mounting. Their movement can be electronically synchronised by a central control system using motion feedback from encoder and sensors on the screw jacks.

Raising and lowering dampers in power station flues, to enable maintenance to be carried out without disrupting power generation.

Power Jacks 2 off 200kN (20 tonne) E-Series metric screw jacks with 4 metre screws, cross linked with a drive shaft and couplings.

At the target station there are 18 beam channels, each with a 30 Te shutter mechanism used during experiments.

Each shutter is operated by a Power Jacks 300kN E-Series Metric Machine Screw Jack type E1829 driven by a 7.5kW geared motor.

The screw jack has an inverted translating screw configuration with 500mm of stroke and 16mm lead driven by a 32:1 worm gear set. The standard design was customised to meet the exact customer installation and operation requirements. The special features ranged from large components such as a special lead screw to nuclear grade grease for screw and gear set lubrication.

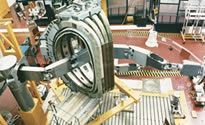

A positioning manipulator used in partnership with the tokamak machine.

Has the ability to carry out key operations, including removing and replacing beam limiter plates located in the outer wall of the Torus. The manipulator has an articulated boom that is 9 metres long and can handle loads weighing up to 1 tonne.

The main tilt and side tilt of the boom is controlled using 200kN E-Series metric machine screw jacks. For the main tilt a screw jack at the rear of the arm levers the arm about a point to angle it in a vertical plane. The screw jack for the side tilt mechanism pivots the arm radially around the central axis running along the length of the arm. For the required precision and accuracy anti-backlash screw jacks were specified in order to minimise positioning error at the end of the manipulator, as movement is magnified along the length of the arm.