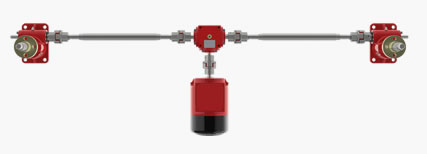

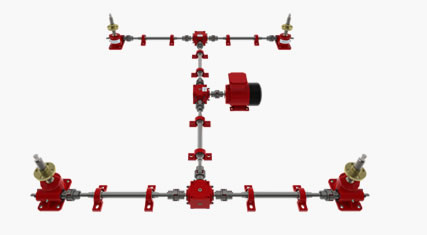

The ability to mechanically link multiple screw jacks together so that they move in unison is one of their greatest advantages. Typical arrangements involve screw jacks, bevel gear boxes, motors, reduction gearboxes, drive shafts, couplings and plummer blocks.

Jacking Systems have 2 main features:

Typically jacking systems are mechanically linked between each driven item in the system. However electronically linked systems are also available. In these systems the screw jacks are individually motorised and synchronised via an electronic control system and closed feedback loop. This can also be expanded so that multiple mechanically linked jacking systems are synchronised / controlled electronically allowing linear motion solutions to be provided on a massive scale.

This has allowed Power Jacks to provide jacking system solutions into most sectors. Production type environments whether in metal, civil, automotive, paper or energy are the main users of jacking systems however applications such as stadiums, communications and research also use jacking systems of small and large designs.

Whatever the application Power Jacks have the knowledge and experience that ensures the customers gets the best jacking system solution.